Eurovac Products

Body Shop Specialized Repair Equipment

OEM Approved Equipment:

Body Repair Certification

EII – Wet Mix Dust Collector (New NFPA 2015 Features)

PART # SYS-050-18300300

- Wet mix dust collector, fabricated from 14 gauge stainless steel which is then thermoset powder coat painted.

- Manual water level system whereby the customer fills the unit with more water when the water level gets to a certain level marked on the site glass.

- Manual drain valve located at the bottom of the separator.

- Initial stainless steel venturi entry for deep penetration into the water, secondary baffles to completely mix the dust particulate with the water whereby no after dry/hepa filter is required.

- Site glass to visually check the water level.

- Automatic low water shut down sensor which prevents the unit from operating if water is not set at proper levels.

- A time delay switch is provided to prevent the start of the dust-producing process (sanding tools) until the collector is in complete operation.

- An off delay time switch is provided which allows the system to run for a set amount of time once the sanding has stopped. This ensures all dust in the hose reaches the collector.

- System includes (2) 25’ lightweight anti-static hose with attached airline

*Patent Pending

EI – Central Wet Mix Dust Collector

- 5, 10 & 20HP regenerative motors are available depending on your needs.

- Electrical control panel , automatic water level control system and automatic hydrogen relief valve. Includes magnetic starter, overload protection with panel mounted stop/start and remote stop/start capability.

- Vacuum relief valve mounted between the separator & pump.

- Wet scrubber, fabricated from 12 gauge steel which is epoxy powder coat painted and treated with zinc oxide and rust inhibitor. (Optional upgrade to stainless steel).

- Automatic water level control system via an ultra sonic probe situated in a reservoir of “quiet” water.

- Manual drain valve located at the bottom of the separator.

- Initial stainless steel venturi entry for deep penetration into the water, secondary baffles to completely mix the dust particulate with the water. Final stainless steel mist eliminator.

- Site glass to visually check the water level.

- Relief valve set to automatically open when system is shut down for exhausting hydrogen gas build-up in an aluminum application.

STRUCTURAL REPAIR CERTIFICATION

Central Fume Extraction System.

PART # SYS-000-FUMEARM0

- 1.5 HP Fan set to produce 900 CFM at 8” W.C.

- 6” x 4m (13.12’) articulated arm (other sizes available)

- Wall mounting bracket

- Self supporting joints and flexible hoses for easy placement with smooth bore tubing for unimpeded air movement

Portable Fume Extraction System – “Box Air”

PART # SYS-070-45006100

- 700 CFM @ Hood

- Spark Trap

- Large Wheels

- Cartridge Filter

- Single phase operation

- Arm Diameter: 6”

- Arm Length: 7

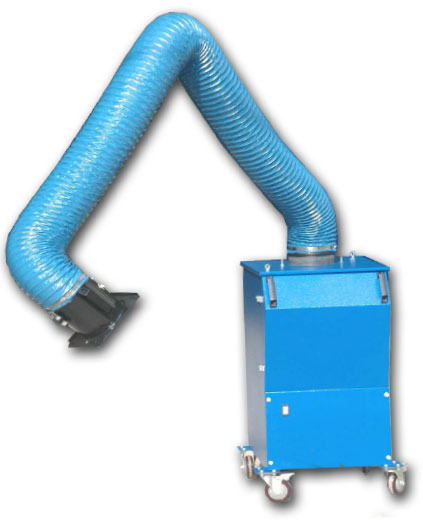

Portable Fume Extraction System – “Rollout”

PART # SYS-070-45106100

- 1 HP Fan set to produce 700 CFM at 8” W.C.

- Three stage high end filtration; aluminum mesh pre-filter which protects the cartridge filter from sparks and prefilters the air, followed by a spun bond polyester cartridge filter, and a final carbon after filter.

- Manual compressed air pulse jet cleaning.