In countless industries – from sophisticated aerospace manufacturing and high-volume woodworking to food processing and metal fabrication – the creation of dust is an unavoidable part of doing business. While often seen as a housekeeping issue, many types of fine dust carry a far more serious risk: the potential for a catastrophic fire or explosion. Understanding and mitigating these risks isn’t just good practice; it’s a legal and moral imperative.

Eurovac has long been at the forefront of providing engineered solutions for handling potentially hazardous materials. We design and build systems that not only clean your facility but, more importantly, help protect your people and your infrastructure from the dangers of combustible dust.

The Hidden Danger: Understanding Combustible Dust Risks

What makes dust combustible? When fine particles of materials like wood, grain, sugar, plastics, chemicals, or metals (especially aluminum and magnesium) are suspended in the air in the right concentration, they can ignite with explosive force. This requires five elements, often called the Dust Explosion Pentagon:

- Fuel: The combustible dust itself.

- Oxygen: Present in the air.

- Ignition Source: A spark, hot surface, or static discharge.

- Dispersion: Dust suspended in the air.

- Confinement: An enclosed space like a room, silo, or dust collector.

Remove any one of these elements, and you can prevent an explosion.

Industries across Canada must adhere to strict regulations set by provincial Occupational Health & Safety Acts and local Fire Codes, which often align with or reference standards set by the National Fire Protection Association (NFPA), such as NFPA 652 (Fundamentals of Combustible Dust). These standards mandate hazard analysis, prevention measures, and protective systems.

Prevention Starts Here: Safe Housekeeping & Source Capture

Effective combustible dust management begins with controlling the dust at its source and practicing rigorous housekeeping.

- Source Capture: The best approach is to capture dust before it can accumulate or become airborne. Eurovac systems, including downdraft tables, fume arms, and direct-tool vacuum attachments, are designed for this purpose.

- Safe Housekeeping: Regular cleaning is vital. Crucially, never use compressed air to blow down surfaces, as this simply disperses dust, potentially creating an explosive cloud. Instead, use vacuums specifically designed for the task. Eurovac offers:

- Explosion-Proof Portables: We provide both electrically certified explosion-proof units and pneumatically driven (Venturi) vacuums, which are inherently explosion-proof as they lack electric motors, making them ideal for high-risk areas.

- Industrial Portable Vacuum Systems: Robust units suitable for various demanding cleaning tasks, available with appropriate safety features.

Handling High-Risk Materials: The Wet Mix Advantage

Certain materials, particularly reactive metals like aluminum, pose an extremely high explosion risk. For these applications, dry vacuuming can be dangerous. Eurovac strongly recommends and provides wet mix solutions:

- Eurovac II Portable High Vacuum Wet Collector: These systems draw the explosive dust into a water bath before it hits any potential ignition source. The water immediately neutralizes the dust’s explosive potential, providing the safest method for handling these volatile materials.

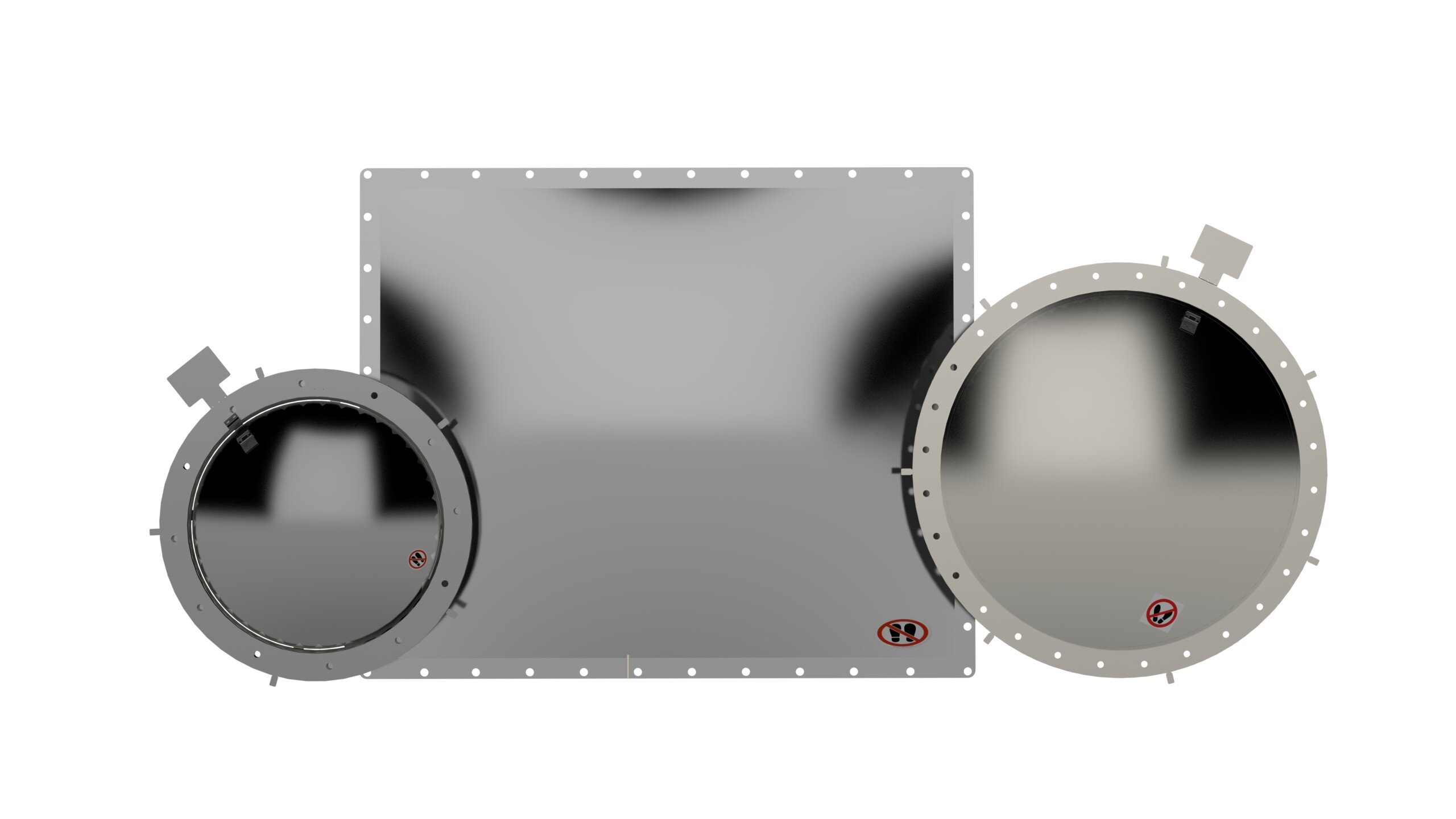

- Wet Mix Separators & Dust Collectors (Wet & Dry): We offer both portable separators and larger wet-type dust collectors for central systems dealing with explosive metals or other specific high-risk dusts.

Engineered for Safety: Eurovac Central Systems & Collectors

For facility-wide dust control, Eurovac’s Industrial Central Vacuum Systems and Dust Collectors can be engineered with critical safety features to comply with NFPA standards:

- Explosion Relief Vents: Designed to safely direct the force of an explosion away from personnel and critical infrastructure, often located on collectors situated outdoors.

- Non-Return Isolation Valves: Prevent a pressure wave or flame front from travelling back through the ductwork into the facility.

- Rotary Air Locks: Provide an air seal at the bottom of a collector, allowing dust removal while preventing flame propagation.

- Grounding & Bonding: Ensuring the entire system is properly grounded to prevent static electricity build-up – a common ignition source.

- Pre-Separators & Interceptors: Can be used to capture larger debris or specific materials before they reach the main collector, enhancing safety and efficiency.

Partnering for Compliance & Safety

Navigating the complexities of combustible dust safety and regulations can be daunting. Eurovac is more than just an equipment supplier; we are your partners in safety. Our team has the expertise to help you assess your risks and design a comprehensive, compliant dust extraction and cleaning system tailored to your specific materials, processes, and facility.

Don’t leave combustible dust safety to chance. Take proactive steps to protect your facility.

- Learn more about our solutions for Explosive Dusts.

- Explore our range of Dust Collectors and Central Systems.

- Contact Eurovac today for an expert consultation on managing combustible dust risks in your facility.